We have been active in plant construction and the processing of stainless steel for more than 50 years. As standard, our stainless steel pressure components are designed and calculated in accordance with AD2000 as well as EN-13445-4. Of course, we also offer design and strength calculations in accordance with ASME regulations. We also have experience in the approval of pressure equipment with the following certifications: PED 2014/68/EU Module A to H/H1, ASME Sec. VIII Div. 1, CRN, KEA, SELO and JIS.

Our design department creates 3D designs with Autodesk Inventor and can provide you with step files on request. Various test procedures are available for quality assurance: Pressure test, endoscopy of weld seams, spray shadow test, dye penetration test, riboflavin test, digital X-ray, roughness measurement, drainability test according to ASME-BPE and others.

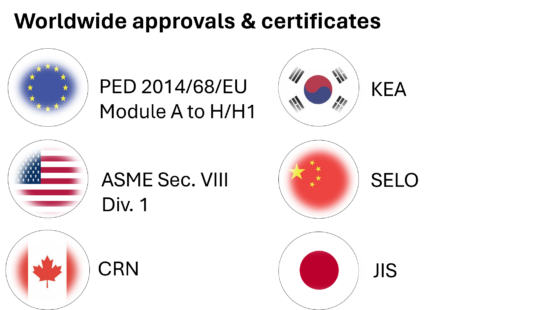

Plant construction

We realise plants for the pharmaceutical industry in accordance with GMP guidelines. In plant construction, we can build structures up to eight metres high and also produce frames and stairs according to your requirements. Your plant can also be piped in accordance with one of the most important American regulations for pipework, ASME B31.3. All high-quality pipework fulfils DIN, ISO or inch dimensions and can also be produced in Hastelloy, Duplex etc. You have the option of carrying out a free FAT (Factory Acceptance Test) at our company before delivery.

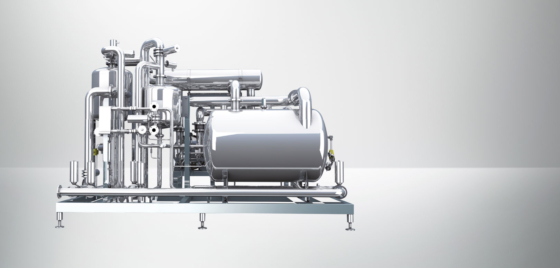

MembraLine® membrane housings

MembraLine® membrane housings are designed to accommodate membrane elements from the microfiltration range up to 160 bar high-pressure reverse osmosis. In addition to accommodating membranes ranging from 1.8″ to 8.3″, in close cooperation with our customers, we also manufacture gas separation housings to accommodate cartridges and modules.

Our latest product from the MembraLine® line is comprised of our ETFE-coated ResiLine® membrane housings, which are used for highly corrosive media, preferably in chemical applications.

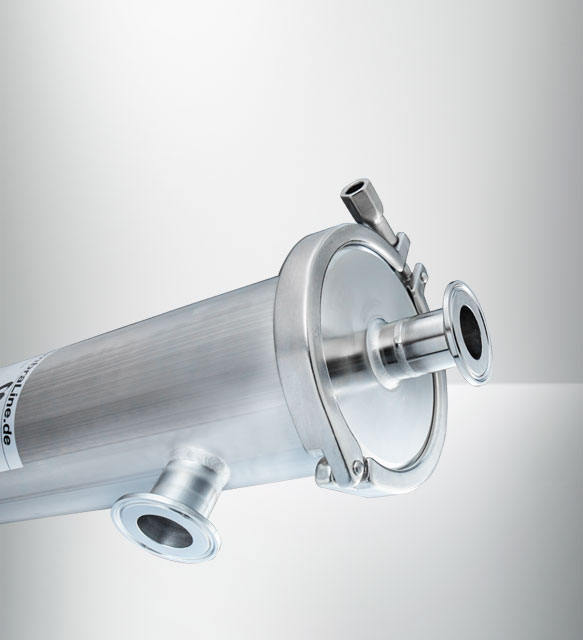

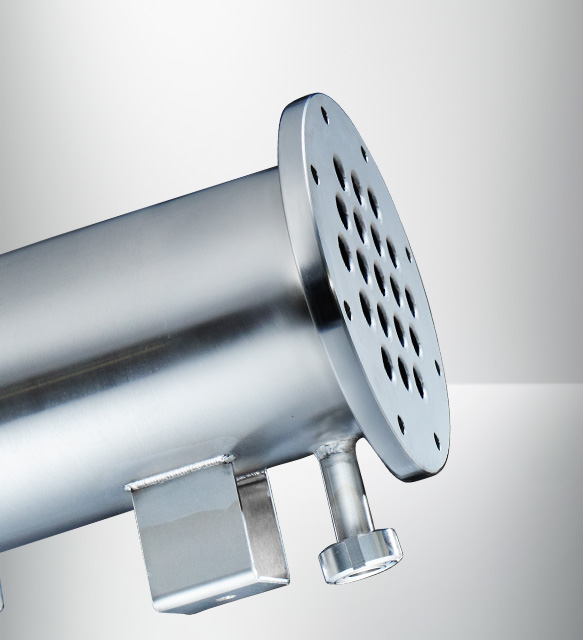

FiltraLine® filter housings

We specify our cartridge filter housings, bag filter housings and modular filter housings depending on the industry, whether healthcare, energy & environmental, semiconductor or food & beverage. The cartridge filter housings can be manufactured as ventilated filter housings, condensate filter housings, inline filter housings and low-volume filter housings from 1-80 cartridges and heatable according to your wishes and specifications. We offer size 1 & 2 bag filter housings with different connections. The module filter housings consist of up to six lens modules arranged one above the other, where the contact pressure of the modules can be changed from the outside. If you have any questions about filter housings requiring approval, please do not hesitate to contact us.

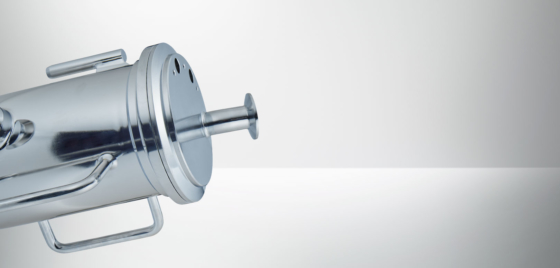

Heat exchanger

Our HexaLine heat exchangers, for which we not only design and manufacture but also perform the thermal calculations for our customers, are available as double-tube heat exchangers and shell-and-tube heat exchangers, also in skid design. We also manufacture DTS (double-tube-sheet) heat exchangers for the pharmaceutical industry.

Tanks

We have 50 years of experience in the manufacture of stainless steel pressure vessels, process vessels, bioreactors, fermenters, agitator vessels and storage tanks. With a volume of 1.5 litres to 1,500 litres, with a heating or cooling jacket, insulating jacket, agitator or bottom outlet valve — you make the decision with us according to your requirements. The tanks are designed in accordance with AD2000, EN13445 or ASME with worldwide acceptance options.

Feel free to contact us. We would be happy to advise you.

Inquire with us; we would be happy to advise you. Our highly specialised team will find the right solution for your requirements.

Feel free to contact us. We would be happy to advise you.

Inquire with us; we would be happy to advise you. Our highly specialised team will find the right solution for your requirements.